Aiag Manual For Spc

Product Code: B-17 The 2D Direct Parts Marking Guideline is a comprehensive document focused on current 2D symbology parts identification methods, the common needs of manufacturing and assembly locations and performance capabilities of various marking and scanning technologies. Covering the marking and reading of Data Matrix and/or QR Code symbols marked directly on parts using laser, dot peen and inkjet technologies, this guideline is intended as a supplement to the AIAG Parts Identification and Tracking Application Standard, B-4.

Product Code: TC-7 An export can be tangible or intangible. A tangible export is a physical shipment or transfer out of the United States (U.S.) of good, technology or software. It can include blueprints, engineering specifications, drawings, clothing, building materials, circuit boards, automotive parts, design plans, retail software packages and technical information. This document is intended to provide a basic awareness related to the topic of export compliance. Readers should not consider this document to provide comprehensive export compliance guidance. Product Code: M-12 This guide serves as an aid for automotive suppliers in the development of their business continuity programs and can be adapted for small, medium and large organizations.

It can also be used to validate an existing business continuity program. This document replaces the original Crisis Management for the Automotive Supply Chain which focused on emergency responses.

It has been expanded to include all elements of business continuity planning including emergency, communications, business resumption planning and IT disaster recovery. Product Code: RC-9 Containers come in a lot of different shapes and sizes from a lot of different suppliers. The Container Performance Test Guidelines, RC-9, provide a common test methodology by which containers can be compared on an objective one-to-one basis. The tests are intended to challenge the containers with forces that are related to the hazards present in their typical handling environments. The tests outlined in this guideline are not validations and cannot predict working load limits, but if you need a consistent means of testing your containers, look.

Product Code: CS-1 This product contains a common set of minimal security guidelines, General Computing Controls, that apply to all 3rd Parties who create, collect, store, transmit, manage, process an OEM's data and information in an environment external to the OEM's. These controls represent the OEM while in the course of doing business and/or providing vital/critical goods or services to the OEM. These security guidelines will focus on the secure exchange and protection of information between the OEM's and their business partners. Product Code: SAEJ2886-K The DRBFM manual describes the basic principles and implementation of the DRBFM process and how it is integrated within the product and process development cycle. The DRBFM manual also provides descriptions and examples of the four steps of the process and their specific advantages and limitations, and guidance of how the analysis is to be carried out for the maximum benefit of the process. The purpose of the SAE J2886 document is to establish a basic understanding of DRBFM and to describe the basic principles and processes of DRBFM. Product Code: I14004-16 Environmental Management Systems - General Guidelines on Implementation, ISO is applicable to any organization, regardless of size, type and nature, and applies to the environmental aspects of its activities, products and services that the organization determines it can either control or influence, considering a life cycle perspective.

The guidance in this International Standard can be used in whole or in part to systematically improve environmental management. It serves to provide additional explanation of the concepts and requireme. Product Code: M-23 The AIAG Finished Vehicle Logistics Quality Handling Manual (developed in partnership with ECG, Association of European Vehicle Logistics), improves operations by reducing duplicated activities and provides a common vehicle handling guideline between the European Union and North America. Standardizing vehicle handling practices globally leads to a reduction in damage rates and the more rapid and effective transporting of vehicles, on haulaway trucks, as well as railcars and ocean carriers.

Product Code: M-22 The process for making transportation claims has evolved. This 2016 update gives you everything you need to know for making transportation claims, including: Global Standard Damage Codes, including Grid Location Diagram and Vehicle 'Splat' Chart; Similarity Matrix Standard; Non Transportation Damage standard, including Photo Sheet; Key Placement Guideline; Inspection and Verification Guideline; Inspection Type Location Guideline; and the newly developed Jumped Chock Codes. Includes new codes and adds an all new inspection verification section t. Product Code: M7-4 Expanding global economic challenges & vehicle demand fluctuation have caused the auto industry to focus on supply chain management issues such as customer requirements, capacity constraints, contingency planning, sub-tier capability, resource allocation, and employee skills. A common tool was needed to help suppliers improve materials management processes.

MMOG/LE is a supplier self-assessment & continuous improvement tool that boosts materials management efficiency & accuracy while reducing costs from error & waste. The tool provides industry. Product Code: CM-3 Members of the Automotive Industry Action Group (AIAG) Conflict Minerals Work Group (CMWG) developed this template assessment to unify the expected quality of supplier responses to the Conflict Minerals Reporting Template (CMRT) formerly known as the EICC-GeSI Template. This template assessment is not to be treated as an alternative to legal advice or used in lieu of due diligence requirements under the rule. Instead, OEMs and Tier-N suppliers may utilize this optional tool to set a consistent response to suppliers and augment their own interna.

Product Code: XO-OHS-1 The document provides guidelines for plants and depots to efficiently and safely segregate and store hazardous materials. The goal of this document is to protect people, property, the environment, and company assets by minimizing the risk of fires, explosions, and hazardous releases resulting from improper storage. As a result of employees using these guidelines, it is intended that packages containing hazardous materials that might react dangerously with one another will not be stored next to each other or in a position that would allow danger. Product Code: OHS-4 Current packaging and containerization are an ergonomic concern and major expense to automotive manufacturers, designers and suppliers.

This new guideline will provide a common approach to container design based on sound ergonomic practices and principles accounting for manual tasks, such as pushing/pulling, lifting/lowering and carrying packages and containers. Using this guideline may result in reduced risk of employee injury in the manual handling of packages and containers and increased productivity and quality. Product Code: I19011-18 ISO provides guidance on auditing management systems, including the principles of auditing, managing an audit program and conducting management system audits, as well as guidance on the evaluation of competence of individuals involved in the audit process.

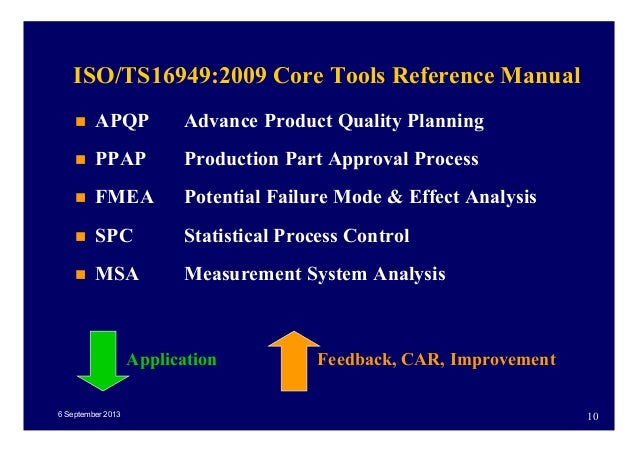

These activities include the individual(s) managing the audit program, auditors and audit teams. It is applicable to all organizations that need to plan and conduct internal or external audits of management systems or manage an audit program. The application of this document to o. Product Code: IATF-1 This standard, coupled with the applicable customer-specific requirements, defines the quality management system requirements for automotive production, service and/or accessory parts. IATF is an autonomous QMS standard that is fully aligned with the structure and requirements of ISO 9001:2015.

However, it is not a stand-alone document, but is implemented as a supplement to, and in conjunction with, ISO 9001:2015, which must be purchased separately. This revised standard cancels and replaces ISO/TS. Product Code: RULES-5 This document contains the Rules for achieving and maintaining IATF recognition related to IATF 16949.

Now in its 5th Edition, the document is commonly referred to as 'Rules 5th'. It includes the criteria for certification body recognition, certification body audit process, certification body auditor qualifications, and IATF 16949 certificates. This document replaces 'Rules 4th Edition' and encompasses previous Sanctioned Interpretations and Rules related Frequently Asked Questions (FAQ's) issued by the IATF prior to the release of this docume. Product Code: I27000-18 ISO/IEC provides the overview of information security management systems (ISMS). It also provides terms and definitions commonly used in the ISMS family of standards.

This document is applicable to all types and sizes of organization (e.g. Commercial enterprises, government agencies, not-for-profit organizations). The terms and definitions provided in this document, cover commonly used terms and definitions in the ISMS family of standards; do not cover all terms and definitions applied within the ISMS family of standards; and do not. Product Code: I15415-11 Information technology Automatic identification and data capture techniques - Bar code symbol print quality test specification - Two-dimensional symbols specifies two methodologies for the measurement of specific attributes of two-dimensional bar code symbols, one of these being applicable to multi-row bar code symbologies and the other to two-dimensional matrix symbologies. This publication defines methods for evaluating and grading these measurements and deriving an overall assessment of symbol quality, and gives information on possible caus. Product Code: I27002-13 ISO/IEC gives guidelines for organizational information security standards and information security management practices including the selection, implementation and management of controls taking into consideration the organization's information security risk environment(s). It is designed to be used by organizations that intend to: select controls within the process of implementing an Information Security Management System based on ISO/IEC 27001; implement commonly accepted information security controls; develop their own informatio.

Product Code: I18046-12 Information Technology. Radio Frequency Identification Device Performance Test Methods. Part 3:Test Methods for Tag Performance. IISO/IEC 18046-3:2012 defines test methods for performance characteristics of RFID tags for item management, and specifies the general requirements and test requirements for tags which are applicable to the selection of the devices for an application. The summary of the test reports forms a unified tag datasheet. It does not apply to testing in relation to regulatory or similar requirements. Product Code: I9001-15 ISO 9001:2015 specifies requirements for a quality management system when an organization.

Needs to demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements. Aims to enhance customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements. All the requirements of ISO 9001:2015 are generic and are intended to be.

Product Code: E-17 The JAIF recognizes that many domestic and joint venture companies have been conducting business in China for several years. During this time, these companies may have developed and implemented B2B messaging methodologies and systems to meet their current needs.

Respecting this situation, the JAIF recommendation serves to guide future investment and development so that collectively, domestic and joint venture companies can more toward and realize the benefits of the JAIF B2B messaging recommendation. Product Code: CQI-8 Key elements of the revised CQI-8 guideline: ' Integrates LPA with management of Key Performance Indicators (KPIs) so that LPAs have a positive impact on business results. ' Expands ownership beyond the Quality function ' Suggests the role of the LPA Planning Team ' Promotes utilization of LPAs in non-manufacturing areas (e.g. Engineering, Purchasing, Program Management, etc.) ' Recommends Roles and Responsibilities for LPA (RASIC chart) ' Provides expanded guidelines for writing effective LPA checksheet questions ' Explains of the audit pro.

The weight of passengers, cargo and options or accessories may reduce the amount you can tow. 2015 gmc yukon denali pickup truck.

Product Code: OHS-8 Undertaken as part of a continued effort by AIAG's Industrial Truck Group to reduce operator strain as well as pedestrian incidents associated with reverse driving, this study was initiated to evaluate the ergonomic and visibility benefits from the operator's standpoint. This involved the trial/demo of four units with rotated operator's compartments and associated features (controls) based on operator feedback. Operator questionnaires and written comments were the input modes for this study. The resulting White Paper does not attempt to. Product Code: D-36 Long Term Archiving & Retrieval of Digital Product Definition Data - Format Recommendation - In today's OEM and supplier companies, storing product definition information has moved to computer based digital management systems. Unfortunately, up to this point there has been no alignment between organizations on storage media, data architecture, authoring/editing software, and hardware infrastructure.

The SASIG Long Term Archival and Retrieval team (LTAR) developed this project to guide the industry in effective, efficient, and common archiva. Product Code: D-38 The AIAG MBE Roadmap Wallchart provides companies; their partners and suppliers a visual means to assess current capabilities and measure their progress from a Level 1- 2D drawing centric environment towards a comprehensive Level 4 - 'Model Based Enterprise'. The Wall Chart identifies the key aspects of drawing/model usage to determine your current MBE level, and highlights where to focus to make the transition to the next level. Achieving the transition to full MBE performance will enable the industry to realize greater product compliance AND. Product Code: RC-16 Packaging Data Forms across various companies are somewhat similar yet all unique. This means suppliers fill out the same data over and over on each unique form.

Various pieces of data needed for the forms can be stored in several different places so a lot of time is spent filling one out and often, within a few days, the same data is needed again for another customer's form. The AIAG Standard Packaging Data Form is designed to eliminate this repetition, saving you time and reducing the potential for error. Product Code: I180007-14 Information Technology - Radio Frequency Identification for Item Management - Part 7: Parameters for Active Air Interface Communications at 433 MHz.

ISO/IEC 18000-7:2014 defines the air interface for radio frequency identification (RFID) devices operating as an active RF tag in the 433 MHz band used in item management applications. It provides a common technical specification for RFID devices that can be used by ISO technical committees developing RFID application standards. ISO/IEC 18000-7:2014 is intended to allow for compatibility and to. Product Code: M-24 Improve quality, prevent damage, and utilize a common standard with the Port Quality Assessment (PQA) tool. The PQA tool was developed to offer Finished Vehicle Logistics personnel a process to identify, record, and improve vehicle quality issues as the vehicle moves through any given port.

Logistics service providers and manufacturers sharing common quality standards improves operational efficiencies by reducing duplication, which leads to a reduction in the damage rates and a more rapid and effective handling of the vehicles. Product Code: I9000-15 ISO 9000:2015 describes the fundamental concepts and principles of quality management which are universally applicable to the following. Organizations seeking sustained success through the implementation of a quality management system.

Customers seeking confidence in an organization's ability to consistently provide products and services conforming to their requirements. Organizations seeking confidence in their supply chain that their product and service requirements will be met, and organizations and interested parties seeking to improve c. Product Code: RC-17 Traditional methods for tracking and controlling the flow and locations of returnable containers have not been robust enough to ensure that suppliers have the right amount of containers, at the right location, at the right time. The result is millions of dollars in extra packaging costs and increased waste in the supply chain. AIAG's Returnable Transport Items Visibility Best Practices provides a number of best practices businesses can employ to increase visibility when sending Returnable Transport Items (RTIs) back to their points of origin. Product Code: I26262-10-12 ISO 262 provides an overview of ISO 26262, as well as giving additional explanations, and is intended to enhance the understanding of the other parts of ISO 26262. It describes the general concepts of ISO 26262 in order to facilitate comprehension.

The explanation expands from general concepts to specific contents. In the case of inconsistencies between ISO 262 and another part of ISO 26262, the requirements, recommendations and information specified in the other part of ISO 26262 apply. Product Code: I26262-5-11 pment at the hardware level for automotive applications, including the following: Requirements for the initiation of product development at the hardware level, specification of the hardware safety requirements, hardware design, hardware architectural metrics, evaluation of violation of the safety goal due to random hardware failures and hardware integration and testing. The requirements of ISO 26262-5:2011 for hardware elements are applicable both to non-programmable and programmable elements, such as ASIC, FPGA and PLD. Furthermore, for pro. Product Code: D-37 The SASIG Long Term Archiving & Retrieval (LTAR) Project developed a set of recommendations to guide companies to implement effective and efficient archival and retrieval practices. The recommendations are partitioned into four topic areas: 1) Format, 2) Process, 3) Time Period, and 4) Quality Assurance.

Aiag Manual For Spc

This document addresses the set of process recommendations. In particular, this document aims to provide a company with the key activities, inputs, outputs, controls and mechanisms needed to fully support the long term archiving and retriev.

Aiag Manual For Msa

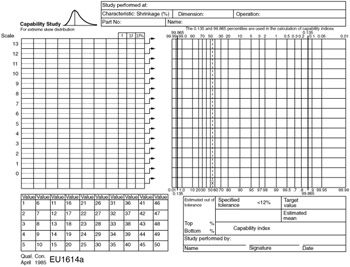

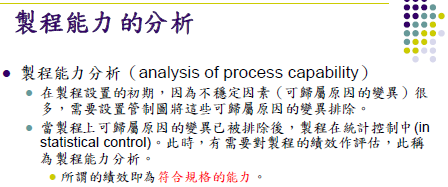

Product Code: CQI-25 The new CQI-25 SPC Quick Start Guide is a supplement to the full SPC Manual and provides the building blocks of statistical process control for those who are new to the topic or have only experienced SPC from a limited perspective. The Quick Start Guide covers about 90 percent of the full manual's SPC applications in a succinct format with text and graphics and includes examples of the most commonly used control charts with easy-to-understand calculation sheets. Suppliers have struggled in the past with quickly finding answers to their SPC-r. Product Code: CQI-26 The SPC Short Run Supplement (CQI-26) guideline was developed to address the particular uniqueness of short run production, where suppliers do not have the production volume to readily apply the approaches identified in the SPC Reference Manual, 2nd Edition. Providing easy to understand examples of commonly used short run charts, the SPC Short Run Supplement is a guideline used to analyze, monitor and control process that do not satisfy the sampling requirements of standard SPC charts. This document is not intended to supplant the SPC Refere. Format Language Member Non-Member Hardcopy & e-Document (Online Only, No Printing) English $45.00 $225.00 Hardcopy & e-Document (Online Only, No Printing) Spanish $45.00 $225.00 Hardcopy English $30.00 $150.00 Hardcopy Spanish $30.00 $150.00 e-Document (Online Only, No Printing) English $30.00 $150.00 e-Document (Online Only, No Printing) Japanese $30.00 $150.00 e-Document (Online Only, No Printing) Korean $30.00 $150.00 e-Document (Online Only, No Printing) Russian $30.00 $150.00 e-Document (Online Only, No Printing) Spanish $30.00 $150.00.

Product Code: CQI-19 Improve product quality and lower cost with the Sub-Tier Supplier Management Process Guideline. Developed to address common issues in the industry, this guideline defines the minimum quality-related requirements for Sub-Tier suppliers and provides explicit guidance on effective identification and control of Pass Through Characteristics (PTC). It also defines the minimum content for use in an organization's supplier risk and quality system assessments, and lists qualifications for supplier development 'coaches', resulting in higher quality and l. Product Code: CQIA-19 AIAG has released a common supplier management process developed by tier 1 automotive suppliers for use with tier 2 suppliers (CQI-19). It focuses on current automaker concerns, e.g. 'pass through' characteristics, risk management, quality involvement in sourcing selection from the pre-selection phase through launch to production monitoring, escalation and development as applicable.

This free Readiness Checklist is a tool for management to use to assess their organization's compliance with the aligned AIAG CQI-19 performance expectations. Product Code: CR-2 Developed by the Globally Harmonized System (GHS) work group at AIAG and the internship program at Purdue-Calumet University as sanctioned by the Chemical Management and Reporting (OHCL) Advisory committee, this easy to use reference document allows the user the to develop GHS compliant Safety Data Sheets (SDS) that meet the requirements of OSHA HCS 2012. Consolidating information scattered throughout the internet in various unrelated databases, this indispensable document covers the new SDS Formatting Requirements; converting existing Materia. Product Code: CQI-22 Most companies typically waste up to 35% of their operating budgets doing things less efficiently than possible or by failing to capitalize on opportunities. The Cost of Poor Quality Guide will help you identify and quantify where inefficiencies exist, effectively communicate these deficiencies to upper management, and prioritize the actions needed for immediate operational improvement and reduction in variance. Take the first step in taking your performance to the next level today!

Following is the letter of AIAG about the new edition of SPC. Subject: SPC Second Edition Reference Manual Now Available The Statistical Process Control Reference Manual, second edition, is now available. This reference manual, published by DaimlerChrysler Corporation, Ford Motor Company and General Motors Corporation, provides an approach to the fundamentals of statistical process control (SPC) based on use in the automotive industry. The manual also establishes a basis for understanding more advanced SPC methods. The SPC, Second Edition has an improved flow. In addition, the Second Edition manual:.

Reinforces the need for a systemic approach to analysis of variation in data. Addresses additional control chart methods and tools, and. Expands and improves coverage of the capability analysis of non-normal data The Statistic Process Control is available exclusively from AIAG at a price of $15 for members and $45 for non-members. To purchase, visit the AIAG Online Store at or fax your completed order form to (248) 799-7995. You can also contact AIAG customer service at (248) 358-3003; however, due to the high volume of calls we recommend ordering your copy online today. Note: This manual is not intended to limit the evolution of SPC methods suited to a particular process or commodity.

Aiag Manual For Spc

Who have read it? Can u give me some evolution information about the new edition? Best Regards, haifeng.