Aem Sander Manual

Running Smooth Over 70 Years For over seventy years, Timesavers has been providing wide belt abrasive finishing machines for sanding wood, metal, plastics, and a wide range of other materials. As a pioneer in sanding technology for the woodworking and machine tool industries, Timesavers leads the way in wide belt sanders. With unmatched service and support, over 50,000 machines in the field today, and factory trained independent distributors; you can be sure that Timesavers will deliver “The finest finish in the world”. Since our founding in 1946, Timesavers has worked tirelessly to meet the unique requirements and specifications of each client we serve, engineering and manufacturing sanding machines that are redefining the woodworking and machine tool industries. Over the years, we’ve partnered with almost every type of manufacturer you can imagine to develop high-quality finishing solutions that offer unequaled performance and reliability.

Humbled by our steady growth, we now provide our revolutionary finishing products through distributors worldwide, helping metalworkers, woodworkers and specialized manufacturers across the planet get more out of their production systems, boosting efficiency, employee safety, reliability and profitability in the process. As one of our customers, we’ll stop at nothing to ensure you find the best machine for your application without overshooting your budget. We’ve become famous for delivering the finest finish in the world, and that’s a reputation we aim to keep for many, many years to come.

Our Commitment to Excellence Whether you’re seeking a new knife planer machine to perform heavy stock removal, upgraded dust collection to keep your worksite clean or a robust slag grinder for effortless dross removal and deburring, you can’t afford to waste your time and money on machines that fail to keep up with your production requirements. That’s where Timesavers comes in.

Here are a few core benefits we offer all of our valued customers. Outstanding Customization Options: The problem with most metalwork and woodwork machinery manufacturers is that they offer very limited customization options, meaning that their machines are only effective on a select handful of applications. This is especially problematic for wood or metalworkers who are dealing with incredibly difficult materials or demanding work processes. After all, no one understands the needs of your shop better than you do. Unlike a vast majority of our competitors, we partner with our customers in choosing the exact specifications they need for each machine they order, including machine widths, head configurations, abrasive belt lengths, brushes, contact drums and more. Outstanding machines that are personally tailored to your production processes, maximizing efficiency and ensuring your machines will continue to perform and excel for years and years.

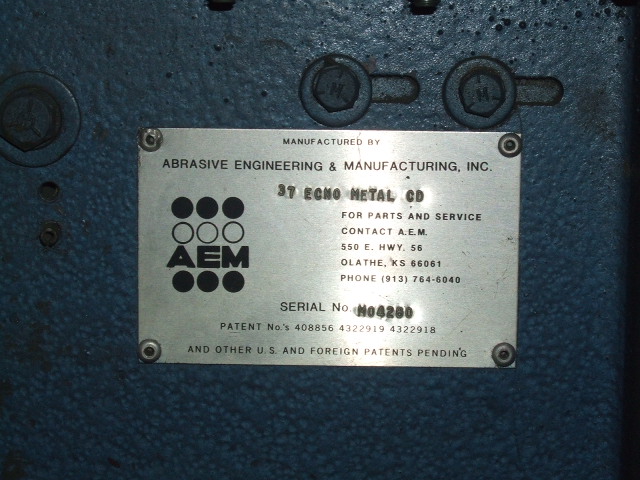

Technical Machine Support Timesavers is fully committed to offering the best customer experience in the industry. That’s why we’re continuously expanding our impressive parts inventory and hiring highly experienced tech professionals, guaranteeing maximum support. Moreover, one of our highest priorities is keeping your machines in peak condition to prevent production downtime. Not only do we offer a dedicated machine parts and service call center to quickly and conveniently answer your questions or concerns, but every machine we sell is engineered, built and supported by our factory-trained and certified machine service techs. Put simply, when you invest in Timesavers, you’ll never worry about finding machine parts and service support again. Parts Nothing can slow your production work down faster than the loss of a critical machine part, especially when you don’t have a replacement on hand. Fortunately, Timesavers can provide your shop with any replacement part for all Timesavers/AEM, Sandingmaster and Grindingmaster machinery at affordable rates, meaning that you won’t have to sacrifice quality or productivity to avoid high maintenance costs.

We use original-quality materials and controlled manufacturing processes when producing our replacements, delivering top-quality parts that will keep your Timesavers machines running like new for countless hours. Service Based in Minneapolis, MN - Timesavers Service Center can provide factory-trained technicians to service any and all Timesavers/AEM, Sandingmaster and Grindingmaster machines in North America. We employ local technicians based out of Minnesota, Pennsylvania, North Carolina, Arizona, and Washington. These industry professionals can travel to your shop to assess and repair damage, verify proper alignment/function, or provide your team with expert training on proper operation/maintenance/Set-up. Who We Help Over our seven decades of experience in the sanding industry, Timesavers has designed production machinery for an extensive variety of applications. Primarily, our mechanical solutions are focused on wet and dry metalworking and woodworking productions, but we also offer high-quality machines for specialized finishing applications. Here’s a brief rundown of the primary customers we serve.

Woodworkers Woodworking is an intricate craft that necessitates familiarity with a number of materials and production strategies. For example, certain woodworking machinery and configurations that work flawlessly for orbital sanding might be completely insufficient for panel sanding. Moreover, certain woodworking processes require highly specialized types of machinery in order to effectively sand through the most durable materials.

Fortunately, Timesavers produces many types of sanders for just about any woodworking application imaginable, including heavy stock removal, panel sanding, wide belt sanding and calibrating, orbital sanding, veneer and lacquer sanding, brush sanding and more. Most importantly, all of these machines can be fully customized for optimal results with the specific materials and production setups your shop utilizes.

For a more detailed look at our full selection of woodworking machinery, be sure to visit our. Whether your team specializes in millwork, furniture or cabinet making, odds are good that we have the perfect sander for you. Metalworkers Like woodworking, each type of metalwork demands a different approach when it comes to creating a smooth edge or perfect finish. This is especially true when contrasting crafts like precision grinding with heavy slag removal, with each requiring finishing machines of vastly different caliber. At Timesavers, we make it easy for metalworkers to find the right machine for each job by creating specialized solutions for deburring, straight grain finishing, edge rounding, calibration, slag removal and more. If you’re fed up with guesswork and taking chances on your metalworking equipment, then we invite you to design your own personalized Timesavers machine, choosing the exact features (including head number, types of heads, wet-vs-dry, abrasives, etc.) you need to attain the best finish possible for your parts and materials. If you want to learn more about our outstanding metalwork machinery, then feel free to check out our.

Special Finishing Manufacturers Woods and metals are far from the only types of materials that benefit from a flawless finish. Many manufacturers dealing in rubber, vinyl, fiberglass, laminates and other special materials are constantly on the lookout for new and more efficient finishing machinery to speed up their production lines and create a more attractive and pristine product for customers and clients.

Aem Sander Replacement Parts

As a result of our acquisition of Dubois Equipment Company, Timesavers can deliver a number of specialty finishing systems for mirror coating, plastic coating, ceiling tiles, glass coating, rubbers, vinyl, concrete, leather and more. Pair these industry-leading solutions with our exceptional dust collection machinery, and it’s no surprise why manufacturers of almost every sandable material in existence trust in Timesavers to make their production processes as fast, productive and safe as possible. For more details on our phenomenal specialty finishing systems and dust collection options, visit our.