Belt Manlift Training Manual

About product and suppliers: Alibaba.com offers 2,599 manual man lift for sale products. About 83% of these are lift tables, 3% are work platforms, and 1% are elevators. A wide variety of manual man lift for sale options are available to you, such as articulated lift, scissor lift, and lift chain. You can also choose from hydraulic, electric motor, and hand. As well as from paid samples.

There are 2,600 manual man lift for sale suppliers, mainly located in Asia. The top supplying countries are China (Mainland), Ethiopia, and Japan, which supply 99%, 1%, and 1% of manual man lift for sale respectively. Manual man lift for sale products are most popular in Eastern Asia, Southeast Asia, and Western Europe. You can ensure product safety by selecting from certified suppliers, including 581 with Other, 568 with ISO9001, and 149 with ISO14001 certification.

UNITED STATES DEPARTMENT OF LABOR MINE SAFETY AND HEALTH ADMINISTRATION Southeastern District Metal and Nonmetal Mine Safety and Health Accident Investigation Report Surface Nonmetal Mine Fatal Machinery Accident Four Corners Mine and Mill IMC Agrico Company Mulberry, Polk County, Florida Mine I.D. 08-01117 February 7, 1998 By Harry L. Verdier Supervisory Mine Inspector Bobby A.

Underwood Mine Safety and Health Inspector George H. Gardner Civil Engineer James L. Angle Mechanical Engineer Originating Office Mine Safety and Health Administration 135 Gemini Circle, Suite 212 Birmingham, Alabama 35209 Martin Rosta District Manager GENERAL INFORMATION Joseph H. Richardson, maintenance mechanic, age 46, was fatally injured at about 11:45 a.m.

On February 7, 1998, when the manlift platform that he was operating overturned. The boom of the manlift had been extended to an almost vertical position and the victim was working from the raised basket. The victim had a total of sixteen years, six months mining experience, all in this job with this company. He had received training in accordance with 30 CFR Part 48. Annual refresher training had been conducted on January 21,1998. Donald Hardcastle, safety manager, notified MSHA of the accident at about 1:10 p.m. On the day of the accident.

An investigation was started the same day. The Four Corners Mine and Mill, an open pit phosphate operation, owned and operated by IMC Agrico Company, was located west of State Road 37 about eighteen miles south of Mulberry, Polk County, Florida. The operating official was Steven Olson, mine manager.

The mine and mill normally operated three, eight-hour shifts a day, seven days a week. Total employment was 405 persons. Phosphate rock was mined by removing the overburden and placing the spoil material in adjacent mined out areas.

Underlying matrix was excavated by large draglines and deposited in shallow sumps or wells where hydraulic guns broke up the material. The resulting slurry was pumped through pipelines to a beneficiation plant for washing, screening, sizing and flotation. Material was put in storage bins, then loaded into railroad cars and transported to chemical plants for futher processing. The last regular inspection of this operation was completed April 2, 1997. Another inspection was conducted at the conclusion of this investigation.

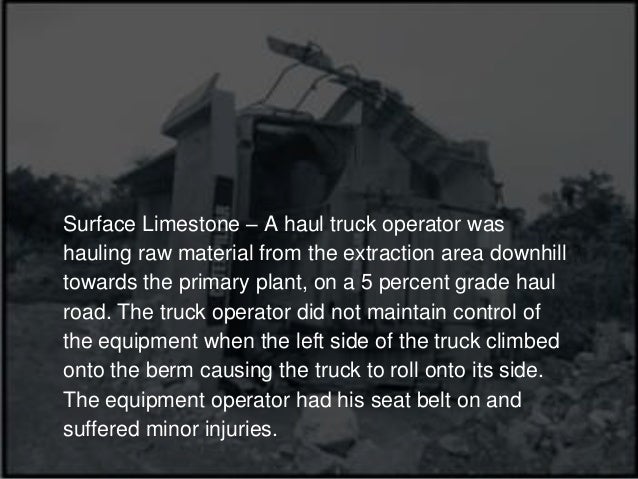

PHYSICAL FACTORS INVOLVED The accident occurred in the heavy media plant at the C-330 hi-mag conveyor belt which was an incline transfer belt that transported material from the plant to a bin. At the time of the accident, employees were working to repair the conveyor belt that had torn apart.

Equipment involved in the accident was a Genie S-60 boom-supported elevating work platform (manlift) manufactured by Genie Industries. This machine consisted of a self-propelled, four-wheel drive chassis, rotating turntable, and telescoping boom which supported a rotating and self-leveling work platform at its end. It was mounted on air-filled rubber tires and was not equipped with outriggers.

The work platform could extend to a maximum height of 60 feet and had a maximum horizontal reach of 51 feet, 9 inches. The wheel base was 8 feet and the wheel spacing was 6 feet. It was equipped with oscillating axle lockout wedges which prevented oscillation when the boom was extended. These wedges were fail-safe and default to an extended position. The net vehicle weight was 25,700 pounds. The manlift was factory equipped with a tilt sensor and alarm which was to activate automatically if the turntable was more than 3 degrees out of level. This alarm was removed and tested in the anechoic chamber at MSHA's Pittsburgh Safety and Health Technology Center.

Testing revealed that the alarm was not functioning properly. The alarm was intended to produce an 85 db tone at a distance of two feet. Measurements indicated that the alarm output was less than 47.6 db which was the background noise level in the chamber. The rated load capacity of the manlift was 650 pounds.

LOCAL OPERATIONS MANUAL: Credit Card Merchant Support Contacts, DSL. A 75% discount on any single specialty juice, specialty coffee or specialty tea. Mar 30, 2015 - This Operations Standards Manual or OSM is written for the employees of ABC Restaurant Company, primarily for those employees involved in. Jun 7, 2017 - When you hear somebody throw around a fancy term like 'restaurant standard operating procedures,' that's great and all, but I bet you just want. Basically, an operations manual should act as an 'instruction manual' for a venue. Recording your systems into an operations manual is an effective way of. Cafe world cheats. The operating procedures for each function of your restaurant can be found in the restaurant's operations manual. It gives all employees of the restaurant.

It was estimated that the victim weighed approximately 200 pounds and that the hand tools in the work platform weighed less than 50 pounds. The manlift conformed to the American National Standards Institute (ANSI) A92.5 standards which required it to remain stable with a 150- pound load applied to the upper perimeter of the platform with the machine on a five (5) degree slope. The manlift was owned by Prime Equipment Company of Mulberry, Florida, and was leased to the mining company. IMC Agrico indicated that all maintenance on the machine, except for checking fluid levels, was performed by the owner. The manlift had been at the mine for about seven months. Measurements and observations at the accident site indicated that, prior to the accident, the platform was fully extended to approximately 55 feet above the ground in its most vertical position. The swing chassis was slewed at approximately 30 degrees.

According to the manufacturer, when in this position, the manlift would have 45% of its weight on the right rear tire. Measurements suggested that the oscillation lock-out wedges were extended at the time of the accident. There was no apparent evidence of any structural failure of the boom, pins, lift cables or other support components. The foundation on which the manlift was operating consisted of a moderately loose rounded phosphate sand pad approximately 2.5 feet above the surrounding ground surface. The maximum slope of the surface of the pad was approximately 5.7 degrees between the left and right tires. The slope in the direction of toppling was approximately 3.9 degrees, and the side slope off the pad varied between 15 and 18 degrees.

In spite of the high contact pressure, examination of the foundation area did not reveal any evidence of major bearing capacity failure or localized slope instability. A significant portion of the pad had been gouged out and obscured by the impact of the turntable of the manlift, but there was no evidence of large ground movement or bearing capacity failure contributing to the failure. There was some apparent settlement of the right rear wheel, which would have caused additional tilt in the chassis of the machine. The magnitude of settlement could not be determined conclusively as the ground surface had been disturbed due to recovery operations and drying of the sand in the area. There was no evidence of deep tire rutting, and any settlement is expected to have been on the order of no more than a few inches. The closest evidence of any tire tracks, and the inferred position of the manlift prior to toppling, was approximately 3 feet from the gouged area at the edge of the pad. The operator's manual specified the tire pressure to be 60 pounds per square inch (psi).

A check of the inflation pressure following the accident revealed that the pressure was 50 psi in three tires and 51 psi in the fourth. The operator's manual indicated that the manlift is not to be used in strong or gusty winds.

Strong and gusty winds were reported in the area of the mine at the time of the accident. A National Weather Service office in Ruskin, Florida, reported wind velocities in Bartow, Florida, of up to 29 MPH at 12:00 noon on the accident date. Measurements at this location were short-duration hourly readings and may not represent the maximum wind velocity. Winds were reportedly blowing from WNW at the accident site. There was no anemometer available on-site to measure the precise wind speed or characteristics. The stability of the manlift was also sensitive to the slope of the ground on which it is sitting.

Free Manlift Training Videos

Calculations provided by the manufacturer, considering machine design and center of gravity under various operating conditions, showed that under static conditions the manlift would be expected to fall if the ground tilt angle exceeded 14.4 degrees. With the wind velocity at 30 miles per hour (mph) the tilt angle at incipient toppling is 11.4 degrees, at 40 mph, 9.0 degrees, and at 52 mph, 3.9 degrees (the slope of the ground in the direction of toppling). It is noted that these are simplified approximations, since the complex dynamic behavior of the machine can not be determined with the limited wind measurement data available.

The possibility that the manlift may have contacted or become engaged in the conveyor belt support structure and subsequently become dislodged causing elastic rebound and toppling was explored. No physical evidence of such contact was found, and none of the eyewitness accounts suggested that this was the case. DESCRIPTION OF ACCIDENT On the day of the accident, Joseph Richardson (victim), along with four co-workers, Billy Hines, McClain Caushy, and Dennis Klein, all maintenance mechanics, and Steven Pridgen, crane operator received a telephone call from their supervisor, Dennis Carlise, at about 3:30 a.m. They were told that a conveyor belt had pulled apart, and to report to work as soon as possible. They all arrived at the mine site between 5:00 and 5:30 a.m. The crew was told by Carlise that the C-330 hi-mag conveyor belt, an incline transfer belt from plant to bin, in the heavy media plant had pulled apart and would need to be repaired.

Caushy and Klein assembled the tools and parts necessary to complete the job, while Hines drove the Genie manlift and Pridgen drove the Grove Rt-740 crane to the area where the work was to be performed. After arriving at the conveyor belt location, Hines positioned the manlift and raised the bucket about 2 feet. From this position, he attached a cable from the Grove crane to the counterweight of the conveyor belt The Grove crane was used to raise the counterweight and a pin was inserted to secure it to the structure, allowing slack in the conveyor belt so repairs could be made. Work progressed normally until about 8:30 a.m.

When the crew stopped for breakfast. During breakfast they talked about the job, and how the repairs were progressing, and also about the wind. The witness's all stated that, although they had discussed the wind, none of them were concerned about it. Earlier in the week, on Wednesday and Friday, conveyor belt repair jobs had been delayed or canceled because of high and gusty winds. At about 9:00 a.m. The crew returned to work, with Klein, Causby, and Hines working on the conveyor belt from the walkway side of the conveyor.

Pridgen returned to the Grove crane and Richardson remained on the ground to operate the manlift. Work continued without incident until about 11:30 a.m., when Richardson received a call on the radio from Carlise. Carlise stated that their lunch had arrived and to come down and eat. Richardson responded that they only had about 30 minutes left to finish the job and they were going to continue before eating lunch. Richardson had made one trip in the manlift to deliver tools and other supplies to the three men working on the conveyor belt. Richardson had extended the boom of the manlift to a height of about 55 feet in an almost vertical position, placing the basket of the manlift along the outside of the conveyor, and passed the tools and supplies across the conveyor belt to his co-workers on the walkway. Richardson was on his second trip in the man basket to take some tools back to ground level.

When he moved the basket away from the conveyor, the basket rocked twice and the manlift fell on its side with Richardson tied off in the basket. Several co-workers rushed to the scene of the accident and a call was placed for emergency assistance. Paramedics and the coroner arrived at the site and Richardson was pronounced dead at the scene. He died as a result of crushing injuries.

Manlift Training Certification

CONCLUSION No single cause was found to be responsible for the accident. It appears that a combination of factors contributed to cause the manlift to become unstable and subsequently topple. Possible contributing factors were the high and gusty winds, the ground conditions where the manlift was parked, and failure to do a complete pre-shift inspection of the manlift prior to placing it in service which allowed the inoperative horn for the level warning device to go undetected. 7786505 was issued on March 10, 1998, under the provisions of Section 104(a) of the Mine Act for violation of CFR: 56.14100(a): A fatal accident occurred at this operation on February 7, 1998, when a Genie S-60 man lift crane with the boom extended approximately 52 feet in an almost vertical position, toppled over, and the basket and boom fell to the ground. An inspection of the crane was not conducted prior to the equipment being placed in service. This citation was terminated on March 25,1998.

Affected employees have been trained on the inspection of equipment, prior to placing that equipment in service. 7786507 was issued on March 10, 1998, under the provisions of Section 104(a) of the Mine Act for violation of CFR: 56.14205: A fatal accident occurred at this operation on February 7, 1998 when a Genie S-60 man lift crane with the boom extended approximately 52 feet in an almost vertical position, toppled over, and the basket and boom fell to the ground. National weather service reported sustained winds of 20 to 30 mph with higher gusts. Tip-over hazards in the operators manual for this equipment warns against raising the platform in strong or gusty winds. This citation was terminated on March 26, 1998. Affected employees have been trained on the manufacturer recommendations for the use of that equipment. 7786509 was issued on March 10, 1998, under the provisions of Section 104(a) of the Mine Act for violation of CFR: 56.14100(b): A fatal accident occurred at this operation on February 7, 1998, when a Genie S-60 man lift crane with the boom extended approximately 52 feet in an almost vertical position, toppled over, and the basket and boom fell to the ground.

Manlift Training Videos

The horn for the level warning device on the man lift crane could not be heard above surrounding noises. This citation was terminated on March 26,1998. Affected employees have been trained on the recognition of equipment defects that affects the safe operation of that equipment. Related Fatal Alert Bulletin.